In this article, we made an injection molding machine maintenance pdf checklist for operators to maintain their injection molding machines. According to this checklist, you will know where to check and maintain it.

Lubrication System

√Lubricating oil pipe → Check in good condition

√Lubrication oil pump → Check pressure normal

√Linear guides → Check lubricating grease enough

√Lubricating pump filter and oil pipe filter → Clean

√Clamp mechanism → Check lubricating grease enough, cleaning off the old grease.

√Oil pump filter → Clean

√Mold adjusting mechanism → Check the lubricating oil enough

√Pre-molding motor → Check the lubricating oil enough

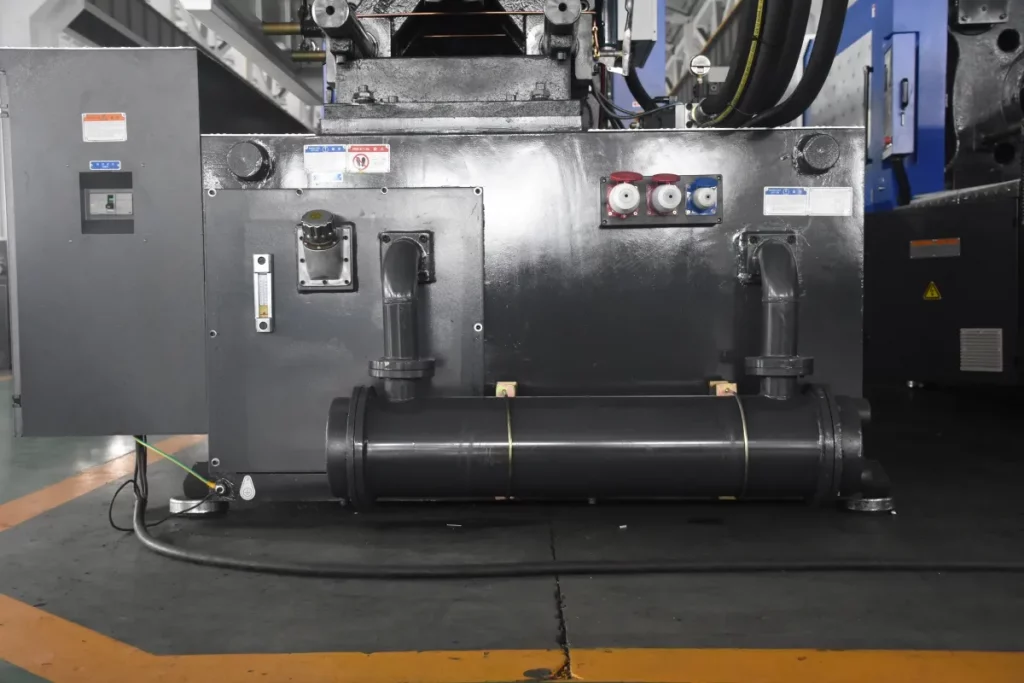

Hydraulic system

√High-pressure oil pipe → Check in good condition

√The oil cylinder seal and piston rod → Check in good condition

√Return oil pressure → Check the pressure ≤4.5 bar

√Oil temperature → Between room temperature~50℃

√All valves → Check in good condition

√Hydraulic motor and mold adjusting motor → Check motors are in good condition

√Oil pump → Check the pressure and speed are normal

√Oil pump motor oil filter → Check in good condition

√Oil tank → Check in good condition

√The oil cooler is normal → Check is in good condition

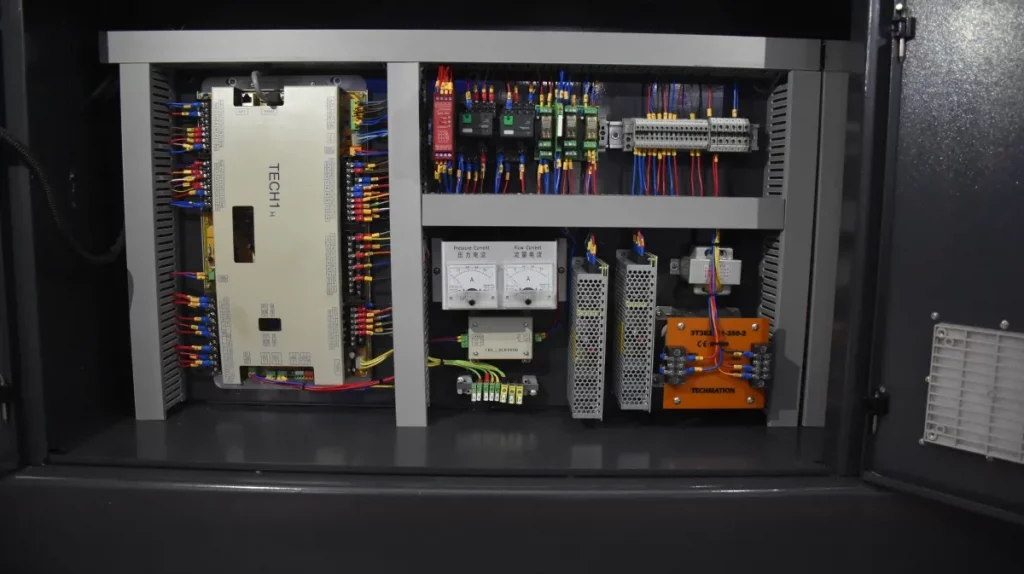

Circuit System

√Power inlet line → Check in good condition

√Main motor → Check the current is normal

√Electric heating system → Check is normal

√Stroke Switch → Check sensitivity is good

√All electric wires → Check the surface is good

√Ground wire → Check is grounded

√Power supply insulation → 100% insulation

√Electrical components → In good condition and cables are not loose

√Check the computer input signal → Sensitive and accurate

√Computer heating signal→ Signals are sensitive and accurate

√Motor start/stop input and output signals → Sensitive and accurate

Clamping system

√Four ties bar and nuts and the parallelism of the template. → In good condition

√Anti-vibration device → In good condition

√Mould clamp machnism sound → Normal

√Clamp posts → In good condition

√Toggle five pivot points → In good condition

√All the nuts → not loose

√Machine horizon level → is horizontal

Injection System

√Barrel and screw → In good conditon

√ Pre-molding motor → Normal and without bad noise

√ Injection rod → Parallel and the seal is in good condition

√ Injection pressure and speed → Consistent with the settings

Shot platform system

√Injection platform → Forward & Backward normal

√Nozzle → Touch the molds and align with mold location hole

√Oil cylinder, oil pipe → No oil leakage

Cooling System

√ The oil cooler → the oil free-flowing

√ The cooler manifold → without water leakage

√ The cooler Temperature → normal

√ Inlet and return ball valve → valve working normal

Conclusion

Above is the injection molding machine maintenance checklist, we hope this could help you deal with daily maintenance jobs. If you want a pdf document, feel free to contact us.