Injection moulding machines are the backbone of the plastics industry. They are the machines that create the plastic parts we use in everything from medical devices to cell phones. Injection moulding machines have many different parts and functions, all of which are necessary for the machine to operate properly.

The injection unit

The injection unit of an injection moulding machine is responsible for injecting the molten plastic into the mould cavity. It is usually composed of an injection screw, a barrel, and a nozzle. The screw is responsible for transporting the plastic from the barrel to the nozzle. The barrel is responsible for heating the plastic to the required temperature. The nozzle is responsible for directing the flow of molten plastic into the mould cavity.

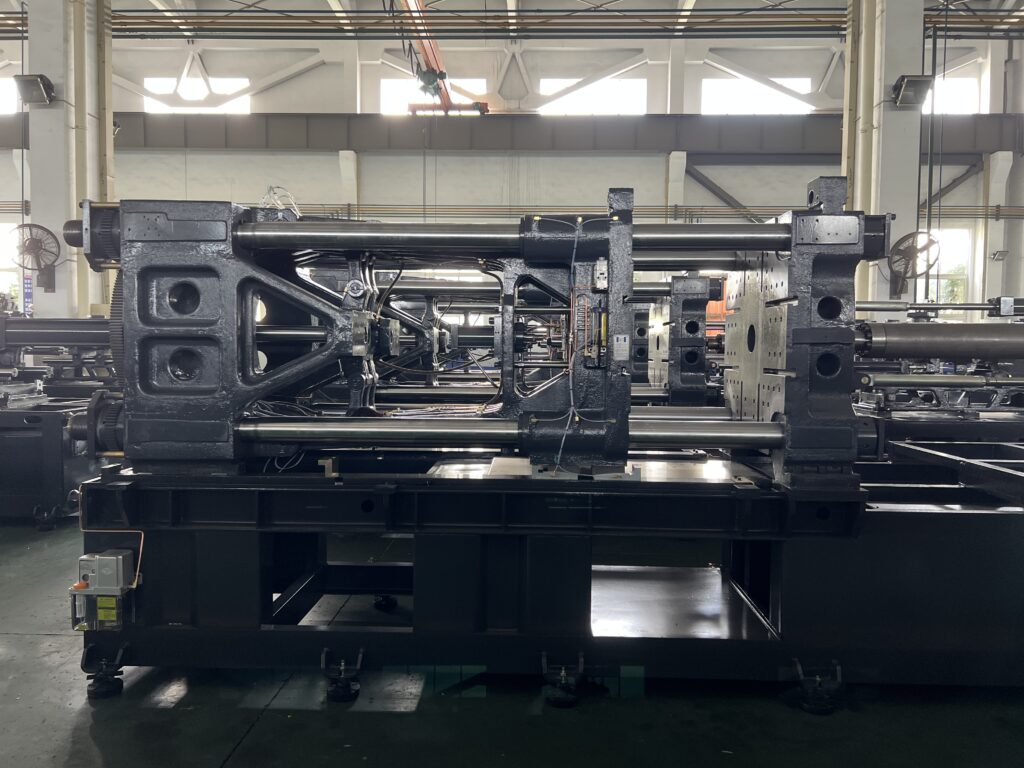

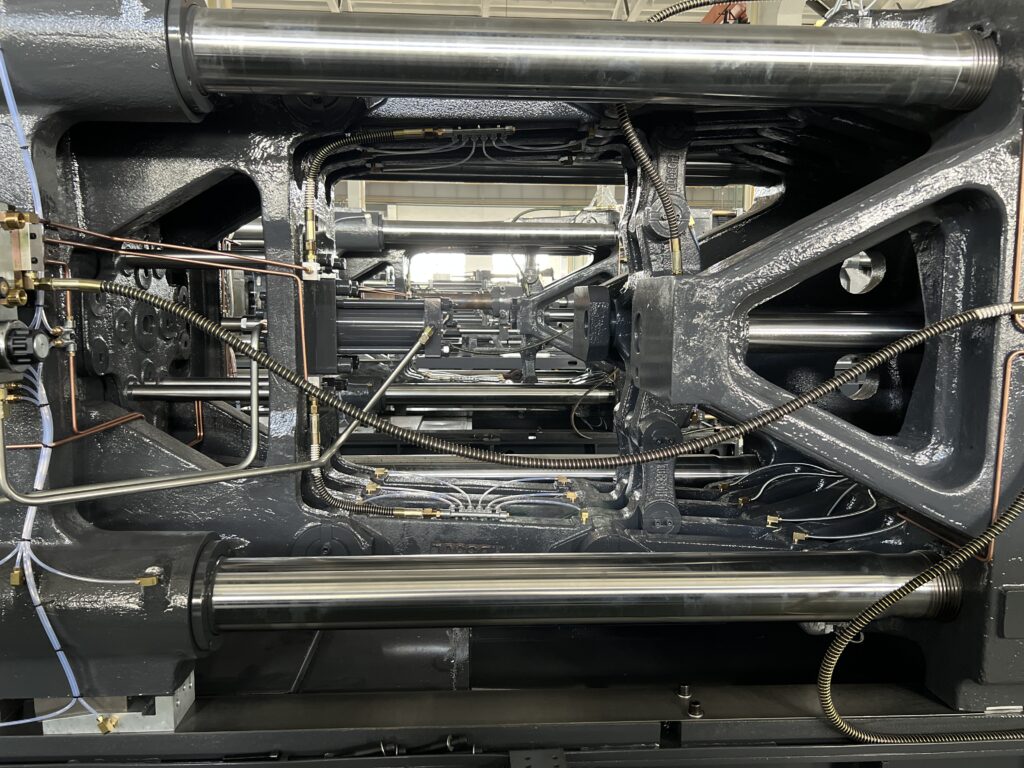

The clamping unit

The clamping unit of an injection moulding machine is a critical component that holds the mould in place during the injection process.The clamping unit consists of the fixed platen and the moving platen. The moving platen has two main functions: to close the mould during the injecting process and to open the mould during the ejection process. The mould is clamped shut by the moving platen during the injection process. The mould is then opened by the moving platen during the ejection process. The clamping force is generated by the hydraulic cylinders. The hydraulic cylinders are connected to the moving platen and supply the clamping force.

The ejection unit

The ejection unit is the part of the machine that removes the plastic part from the mould after it has cooled and solidified. It consists of a series of pins that are driven into the mould cavity, pushing the finished product out. The ejection unit must operate quickly and smoothly so the mould can be replaced and the next plastic part can be made.

The control unit

The control unit is the heart of an injection moulding machine. It controls all the machine’s functions, from heating the plastic to injecting it into the mould. The control unit is typically made up of a touchscreen interface, through which the operator can input instructions and several sensors and actuators. The control unit is also connected to the machine’s power supply and hydraulic system.

These are just some of the most critical parts of an injection moulding machine. Many other parts and components make up the machine, which is vital to its operation.