How much does a PET preform manufacturing plant cost? In this article, we will give you a comprehensive guide to opening a pet preform plant.

Is PET preform manufacturing a good business?

If you want to open a new business to make PET bottles preform in developed countries like the USA, it will be an adventure. There are so many big brands with highly mature and automated making lines to decrease the cost to a deficient level. Small PET bottle workshops can’t live in a fully competitive market.

However, there is a different case in the emerging markets. No giant predator and PET perform demands still in large quantities. So PET preform bottle manufacturing is still a good business.

How to establish a pet preform plant, and how much money does a PET preform manufacture costs?

How to look for the best pet preform making machine?…

So many explosive questions are bothering you. Don’t worry. I will clarify all these questions with brevity and comprehensive outlines.

How much does a pet preform manufacturing plant cost?

Some people new to the PET preform manufacturing field often want to know what is PET preform manufacturing plant costs. That’s people caring about and eager to learn. There are many other similar questions, like what’s the pet preform machine cost?

In general, the pet preform manufacturing plant cost according to the scale of the PET preform factory daily output, and the daily capacities determine the machines quantities. Thus, the price depends on how many pet preforms you want to make daily. Large machines can accommodate more giant moulds, including more cavities; the output of PET preform per day would be larger.

Therefore, if you want to know about the specific cost of PET preform machines, please kindly provide us with some more concrete information about your PET preform, like the size, weight, annual capacities. But if you are new in the industry, please feel free to contact us; we have many mature plans for your reference. We are one of the most famous pet preform machine manufacturers in china. You can check the China injection moulding machine rank list on the China Plastics Machinery Industry Association website.

So let’s talk about our PET preform injection molding machine plans for our customers’ reference.

Currently, we primarily have three pet bottle preform making machines in our pet preform injection machine family.

290 Ton PET preform machine, 330 Ton PET preform making machine, 390 Ton PET preform injection machine, they differ in shot weight, clamping force, mold size and other parameters.

It’s complex to list all the pet bottle preform machines here, I will take the 390Ton pet bottle injection moulding machine as an example to give you a clear comprehension about the 28mm 13g 64 cavities water bottle performs manufacturing.

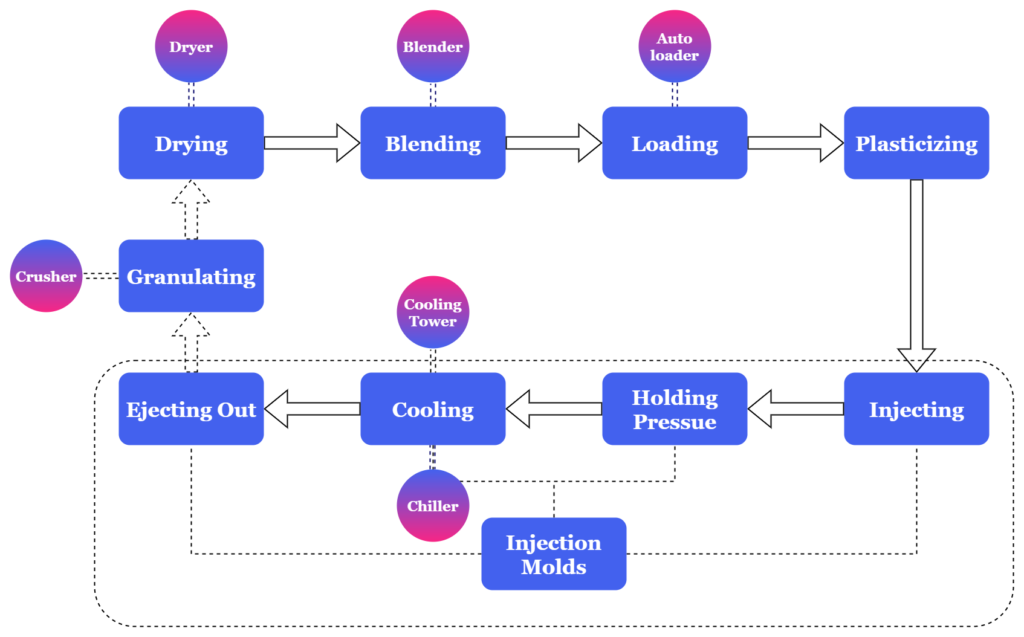

PET preforms manufacturing process

- PET materials need to be dried first before going to the cylinder, in this process requiring a machine called a hopper dry

- Some customers want to make coloured preform, like blue 5Gallon 20L pet preforms, while in this process needing equipment called a colour mixer; however, if you need more precisely meter the colour weight, another small equipment dosers would be required.

- After drying and blending with masterbatches, PET materials are sent into cylinders with autoloader equipment, which can load PET particles into the cylinder’s inlet hopper. With cylinder heating and screw rotating heat, the plastic particles would be melt.

- The PET plasticized melted flow would be injected into a mold. After flowing to the end of the cavities, the machines still hold pressure to shape the PET preforms, and after that, PET preform mold would be cooled with cooling water from chillers.

- After cooling and shaping well, PET preforms would be ejected by machine ejectors.

So far, the whole cycle has finished.

With a clear explanation, you better understand the whole PET preform manufacturing process and how much plastic auxiliary equipment is included in the entire PET preform making line. You may want to know pet preform machine cost immediately.

PET bottle preform machine price

PET preform machine price ranges from size to size, and the bigger PET preform injection molding machine price is higher, smaller pet preform manufacturing machine price is lower. Meanwhile, the steel price fluctuating leads to pet preform machine cost changing, especially during COVID-19. Thus here I will give you an approximate price of all these plastic machines.

| Machine Model | Quantity (pcs) | Price (USD) |

| 390 Ton PET preform molding machine hs code for PET preform machine: 8474809090 | 1 | 75,000.00 |

| 800kg PET Material Hopper dryer | 1 | 5,000.00 |

| 2.5Hp Autoloader | 1 | 1,000.00 |

| 200kg Color Mixer/Blender | 1 | 1,800.00 |

| 11kw Crusher/Granulator | 1 | 2,300.00 |

| 40Hp Air Chiller | 1 | 16,300.00 |

| Air Compressor BK15-10 with air tank | 1 | 4,200.00 |

| 50Ton Cooling Tower | 1 | 2,300.00 |

| 13g 64 Cavities PET preform hot runner mould | 1 | 70,000.00 |

| Total price(USD) | 9 | 177,900.00 |

Note: this is just an approximate cost of the PET preform molding machine, specific cost need to evaluate the PET preform demanding output, size, and weight. If you are still confused about it, pls feel free to contact us. Furthermore, if you want to know information about our pet preform machine for sale, please rest assured to contact our sales team.

The best pet preform machine

Customers often want to buy the best PET preform machine, what is the best?

There are not the best PET preform machines, just the most suitable machine. When you take price, quality, and service into consideration, you will find you are looking for the most appropriate machine which suits your conditions. While our machines are cost-effective, maybe not the best machines, choosing them is also the right choice.

HS code for PET preform machine

When importing PET preform machine from China, you may want to know the hs code of PET preform machine. There are two hs codes applicable for pet preform machines.

8474809090, 8477101010, 8477101090, 8477109000, 8477209000.

PET preform injection molding machine troubleshooting

Another question customers care about most, how to address PET preform injection molding machine troubleshooting?

In some regions, we have an agency there that could provide a troubleshooting service for you. In other regions, we provide online troubleshooting services or free accessories shipping to our customers instead.

Summary

PET preform manufacturing is still a good business in developing countries like Africa, South-East Asia, where labour costs are lower and the markets are not very competitive.

You could also find some other niche markets like PET candy cans and PET preform for 5Gallon water buckets. If you want to know more details and videos about PET preform machines, please feel free to contact us.