This article is a comprehensive guide for choosing a plastic spoon making machine.

With the global pandemic of COVID-19, people increasingly tend to use disposable cutlery when going out to dinner.

In addition, disposable cutlery reduces the risk of infection, as these are abandoned after single-use.

Reports said Coronavirus would stay on plastic and stainless steel cutlery for three days.

The best way to prevent virus spread is using sing-use cutlery alternatives.

With the virus pandemic and online food service becoming popular, global disposable cutlery consumption is forecasted to rise.

The consumption of plastic spoons, knives, forks increased rapidly, spoon making business may be a good choice at the moment.

Plastic cutlery manufacturing process

Material for plastic spoon

Generally, manufacturers use PP(Polypropylene) or PS(Polystyrene) materials to make plastic spoons, forks, knives.

PP material cutlery is more resilient, while PS material cutlery has a higher hardness, and PS cutlery is more premium.

We have many types of plastic spoons, forks, knives for your reference.

Please feel free to get samples. PP cutlery, PS cutlery images

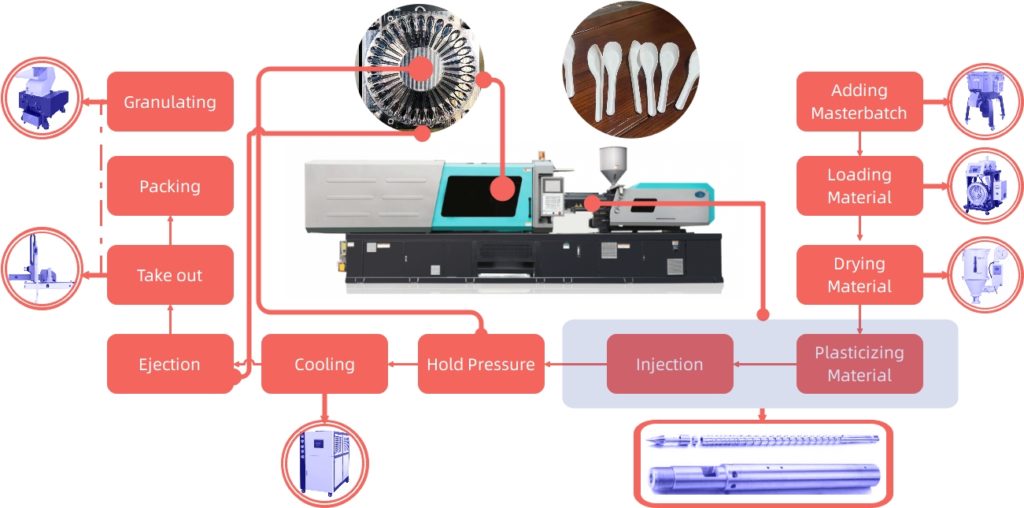

Manufacturing process for plastic cutlery

Like all other plastic products manufacturing, the first step is preparing materials, including blending materials and masterbatches with plastic color mixer, drying materials with hopper dryer, and loading materials by the autoloader.

After the materials are pre-processed, with the screw rotating and heater heating, they will be plasticized.

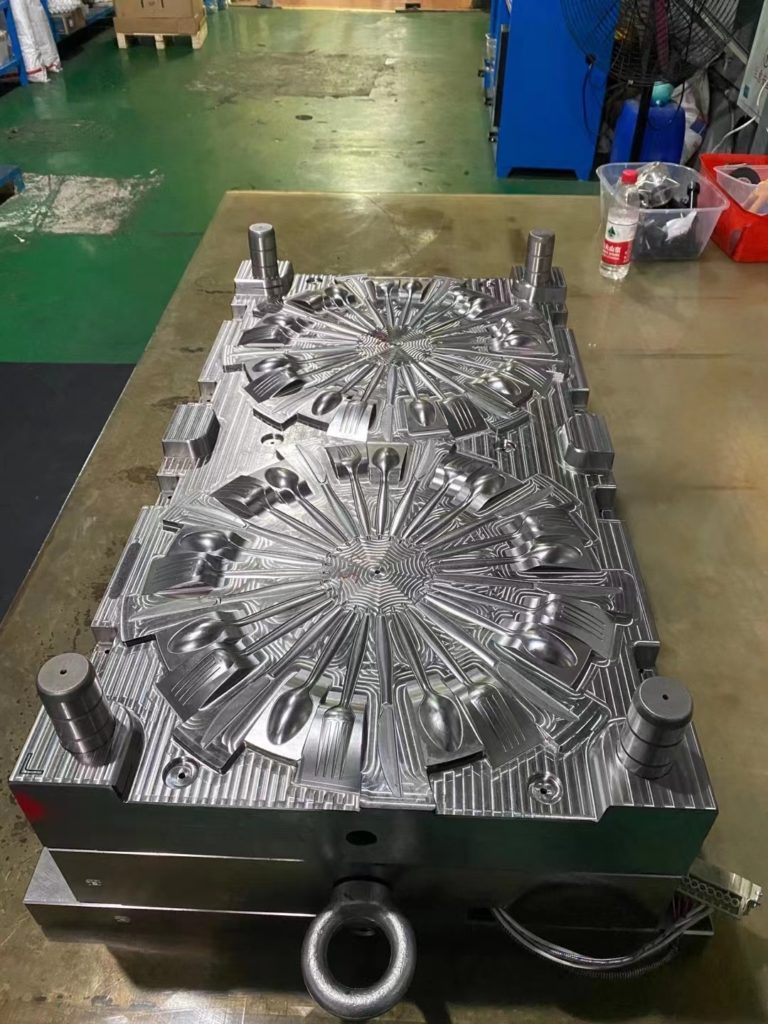

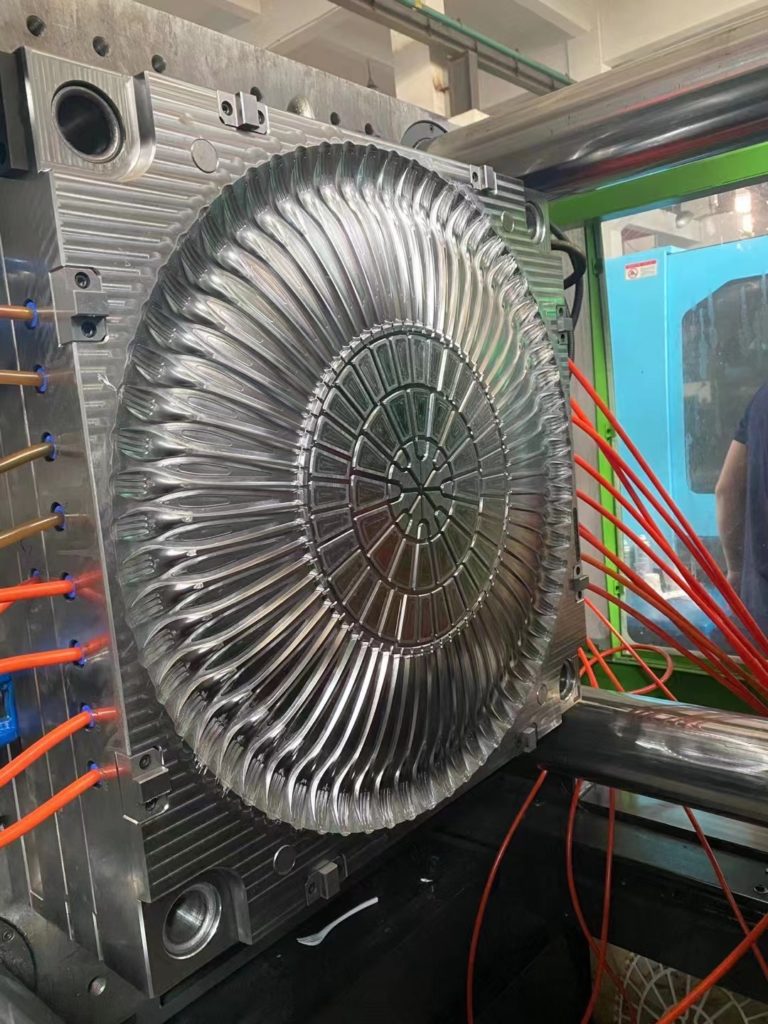

Then melting plastics would be injected into molds, the molds would be clamped and hold the pressure to let cutleries be molded.

Meanwhile, chiller will deliver mold’s heat away, the mold is cooled, and the cutleries shaped.

Next up, plastic cutleries would be ejected by mold ejectors, and the robot will take them out and put them on the conveyor.

If the plastic spoons and forks knives were perfect, they would be sent to the following packing process.

On the contrary, if they are not good, they would be collected and sent to the granulating process with a granulator.

Above is the whole manufacturing process for plastic cutlery.

Automatic plastic spoon making machine

Here, we want to give a clear clarification about the automatic plastic spoon making machine.

This automatic plastic cutlery manufacturing system includes a high-speed injection machine, a three-axis servo robot, a packing machine, and other plastic auxiliary equipment.

High-speed injection machines can provide a fast speed of nearly 9-10s cycle time, and with the servo robot and packing machine, the whole process would decrease to 12s, which is highly effective and reduces the labour cost.

Plastic spoon making machine cost

Now you may want to know the plastic spoon making machine price.

I will give you an approximate budget, including the spoon making machine price, disposable plastic spoons forks knives molds price, three-axis servo robot price, packing machine price, and other auxiliary equipment prices.

You may find some clues from this price list and get an overall comprehension of the plastic spoon and fork making machine profit margin.

Comparing your budget, you will make a better decision to start a spoon making business or not.

Annual capacity

How much is the annual capacity of the above plastic spoon making machine?

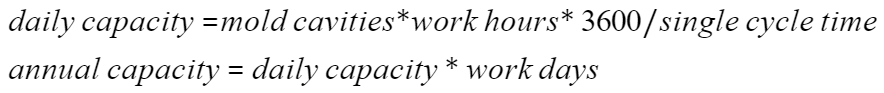

Here we have an approximate formula on how to calculate annual capacity.

According to the formula, we need to know the mold cavities, working hours per day, working days per month, or year.

On the above plastic spoon making line, spoon mold cavities are 32, let’s assume they work 8hours per day, 300days per year, and we already know the fast injection machines cycle time is 10s.

So the daily capacity = 3283600/10 = 92,160 pcs per day.

The annual capacity = 300*92160 = 27,648,000 pcs per year.

Final Thoughts

With the plastic spoon making machine price list, annual capacity, material cost, labour cost, electricity cost, you could calculate the total costs to start a cutlery making line.

If you are busy and don’t want to do mathematics, feel free to contact us.

We will provide a specific cost budget quotation to you.